How To Troubleshoot Common Issues with Power Modules

How To Troubleshoot Common Issues With Power Modules

Image source Freepik

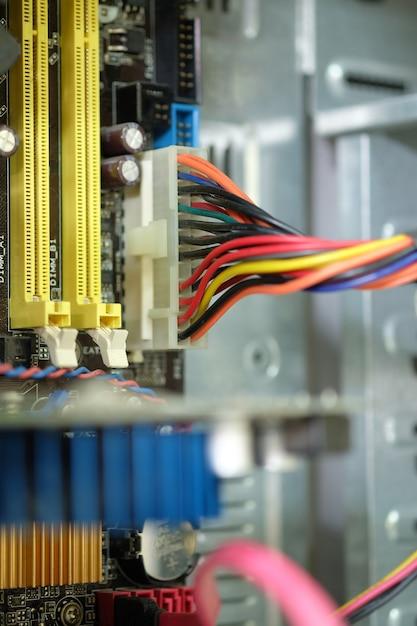

My device or appliance is not working. The first culprit you will likely blame for this problem is the power module. This is part or section of an electronic device responsible for power management. All the operations that entail the use and management of electric energy will always require power modules. So, when a device is showing no signs of running even after it has been turned on, our first stop will be on the power module. Many other issues and problems still point out to issues related to the power module. In this article, we are going to learn how to troubleshoot common issues with power modules.

Poor wiring and connections

This is one of the most common issues that affect power modules. It is caused by poor positioning of the wires and other connecting elements. The issue is characterized by constant power loss on the device. Your device or appliance turns off unexpectedly when it is running. In other cases, some modules or components of a device fail to run when others are running.

Solution

It is easy to troubleshoot issues related to poor wiring and connection. Just take your time to trace all the wires and the cables that are connected to the power module. Ensure that they are in good condition and are connected properly either to the power source or to the auxiliary devices. Other than wiring, you should also inspect the positioning of other components that are connected to the power module. Poor positioning can affect the connections hence interfering with the flow of power from the power modules.

In case the issue is due to damaged wires and other power-related components, then you should consider doing a replacement. Buy quality wires that will replace the damaged ones. As a precautionary tip, you should avoid buying used power modules. This is because there is a high chance that they already have faulty connections.

Thermal issues

Heat is another common issue that affects power modules. Being a module that performs power management functions, it is prone to frequent overheating. Heat is one of the byproducts of electric current that is flowing through the module. This heat is usually due to the internal resistance in the components and wires in the module.

While there is an acceptable level of heat in the power modules, you should be worried about overheating. This is when the heat in the module exceeds a specific threshold. You should also be concerned about frequent overheating in the module. It could be a sign of an underlying issue that requires your full attention.

Solution

Troubleshooting thermal issues starts with identifying the source of the problem. First, find out the state of all the thermal management components such as heat fans, heat sinks, and vents, among others. Ensure that they are in perfect condition. The fan should be functional. In case they have accumulated dust, you should clean them. Repair and replace all the damaged thermal management components.

The heating problem could also be due to a fault in the power management. Some components could be damaged hence dissipating excess power. Inspect the state of these components and make necessary replacements. Even after making the necessary changes, you should still monitor the thermal behavior of the power module.

Overcurrent and overvoltage

Every device has a defined current and voltage rating. However, there are incidences when the device is bombarded with high currents and voltage. Since most power modules have protective elements, they will shut down to minimize any possibilities of physical and electrical damage. However, sometimes this problem could persist.

Solution

Verify that all the power management components are in perfect working condition. In case it is a new device, you should test and verify the power ratings of all the critical components that make up a power module.

You should also check the external power source that supplies electricity to the power module. It could be the main cause of all these troubles. Ensure that it is in good condition so that there is no leakage of excess current.

Current leakage

Current leakage is another issue that tends to affect power modules. This is the unwanted current that usually finds its way to the conductive parts of an electronic device. Other than significant wastage of energy, current leakage is also a major safety risk. Electrocution is the biggest safety hazard that is caused by current leakage. There are cases of fire caused by current leakage.

Solution

The most basic solution to current leakage is component placement. Ensure that all the components are properly isolated. This will minimize resistance between them. Also, ensure that all the wires and connecting components are properly insulated.

Diagnosing power modules: What you should know

We have just looked at various ways of diagnosing power modules. But, how can I know that there is an issue with the power module of my system? It all starts with making a proper diagnosis. This process entails conducting thorough checks on the modules to unravel all sorts of issues that are affecting the performance and functionality of the module. Let’s look at various techniques for diagnosing power modules:

· Physical inspection: This is the easiest way of diagnosing power modules. The fact that the modules are in physical form means that you can easily detect some issues by conducting physical checks and inspections. You will take note of all signs of physical damage such as scratches and breakages on the surface of the power modules.

· Optical microscopy: This technique entails using an electric microscope to inspect a power module All the flaws that were not visible to your naked eye will be revealed. This method is also ideal whenever you want to conduct a cross-sectional inspection of the power modules.

· Micro-sectioning analysis: You should implement this technique immediately after conducting a general physical inspection of the power module. Here, each section of the module is handled separately. By doing so, inspectors will be able to find or detect even the smallest issue that is affecting the operation and performance of the power module. Micro-sectional analysis may force a technician to disassemble the power module to access those hard-to-reach sections.

· X-ray analysis: Here, you will use an X-ray machine to analyze power modules to detect possible flaws. It makes it possible to scan the deepest sections of the power module and you will also be able to detect the smallest problem on the module. An advantage of using X-ray analysis is it has zero impact on the operation of the power modules.

Once you implement these techniques, there is a high chance that you will be in a position to detect all the issues on your power module. From there, you can proceed with the troubleshooting process.

Consider getting quality power modules

Are you dealing with constant issues with your power modules? Perhaps the problem could be with the quality of the modules. Low-quality power modules are likely to have many issues. Additionally, some issues could be due to damaged components on the power modules. The best way of dealing with such issues is to come up with a proper replacement plan. You should consider buying new power modules that will replace the old and damaged ones.

When it comes to buying new power modules, start by checking their features and specifications. They should be compatible with the old application that you built. The specification includes power requirements and even physical dimensions.

The next attribute that you should pay attention to is the quality of the power module. Ensure that the modules are from eatable brands. The manufacturers should be known for building quality power modules for different applications.

The right way of doing things is by buying from the best power module suppliers and distributors. Such entities are known for their commitment to sourcing quality power modules from the best manufacturers.

Conclusion

While you may not want anything bad to happen to your power module, some issues are inevitable. The good news is you can get around most issues related to the power modules. Just implement the troubleshooting tips that we have discussed here and everything will be back to normalcy. From the guide, it is clear that there is a variation in the complexity of most issues. Some are simple to solve while others are quite complex. You should strive to solve the ones that you can. Just use the guidelines that we have given. In case the issue is too big for you to handle, then you should consider leaving it to an expert to solve.

Some of the power module issues require that you replace devices and components. Always ensure that you replace them with high-quality components that will deliver better results. Such components are only found from the best sources. This is where Rantle East Electronic comes in. We are a reputable global distributor of power modules and all the related components. You should consider working with us in case you need premium-grade power modules for your devices and applications.

Kevin Chen

Founder / Writer at Rantle East Electronic Trading Co.,Limited

I am Kevin Chen, I graduated from University of Electronic Science and Technology of China in 2000. I am an electrical and electronic engineer with 23 years of experience, in charge of writting content for ICRFQ. I am willing use my experiences to create reliable and necessary electronic information to help our readers. We welcome readers to engage with us on various topics related to electronics such as IC chips, Diode, Transistor, Module, Relay, opticalcoupler, Connectors etc. Please feel free to share your thoughts and questions on these subjects with us. We look forward to hearing from you!

Start With

Start With Include With

Include With