BGA package vs CSP package: What's the difference?

BGA package vs CSP package: What's the difference?

Image source Electronics Stack Exchange

Are you planning to buy integrated circuits? One of the things that you will focus on is the packaging. It entails the enclosure and the protection that the IC has.

There are different IC packaging methods and each has unique features, pros, and cons. As a buyer, you must know the details of each packaging technique that has been used before you even consider making that purchase.

When it comes to IC packaging, many people tend to confuse BGA and CSP packages. They are popular packaging techniques that are used in integrated circuits.

In this article, you are going to learn about BGA and CSP IC packages. We will explain how these packaging methods are used, and when they are used. Furthermore, you will get to know the differences between BGA and CSP packages.

What is the BGA package?

Ball grid array package is a type of surface mount technology that is used for the packaging of integrated circuits. It features numerous layers that overlap each other. Each layer comprises of millions of components, logic gates, and even complete electric circuits.

It is referred to as a ‘ball grid’ because the package tends to form numerous spherical bumps on the back of the printed substrate. This is unlike other IC packages where the back is characterized by leads that end up forming several pins. Additionally, the balls form rows hence the name array.

The package body of a BGA is small and compact. Also, the ball-like structures at the back of the substrate mean that you don’t have to worry about the deformation of the pins. This is quite a common problem in the QFP IC packaging technique.

BGA comprises of both conducting and insulting layers that are supported to their respective positions by a solder mask. This mask also provides protection against the impact of oxidation on the electronic components on the PCB. Copper is the main material for the BGA’s conducting layer, while epoxy resin makes up the insulating layer.

BGA has evolved to become a go-to packaging method for a wide range of applications. It is even suitable for intensive electronic applications such as CPUs. Versatility and reliability ate among the top features that characterize BGA packaging method.

Types of BGA packaging

BGA packaging is further categorized into different classes which are:

· Plastic BGA: This packaging features a multi-layer board that has layers of different materials. Usually, the number of layers should not be more than four.

· Ceramic BGA (CMBGA): In this type of BGA packaging an electric connection is placed in-between the ceramic substrate. It is quite common on the Intel series of CPUs.

· Flip Chip BGA (FCBGA): This type of BGA packaging features both the multilayer and rigid substrate.

· Tape BGA substrate(TBGA): This type of BGA package is designed to form a strip-like shape. It has a maximum of two layers.

· Clarity Down PBGA: This BGA package features a bare chip section which is also known as a cavity. This area is located right at the center of the package.

What is a CSP package?

Chip-scale package (CSP) is a type of IC package that is surface mountable and its area or size does not exceed 1.2 times the size of the actual die. Since it was invented, it has evolved to become one of the hottest things in the semiconductor chip packaging industry.

Even though the chip-scale package tends to focus on the size of the IC, it pays very minimal attention to the structural elements of the chip.

There are different forms and categories of CSP. The most common ones include wire-bonded flip-flop and non-flip-flop packages. Each is designed to meet the specific needs of IC packaging.

Chips-scale packages come with an array of advantages that you may not find in most traditional semiconductor chip packaging methods. Size reduction and increased number of connections are just among the top benefits.

Differences between BGA vs CSP packages

Now that you know the basics of these two IC packages, let’s cover different areas in which BGA is different from the CSP IC package.

Size and dimension

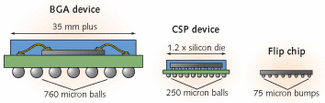

There is a slight difference in terms of the form factor between BGA and CSP. BGA covers a slightly larger surface area than the CSP IC package. The size of BGA is usually determined by the number of balls and the desired distance between two adjacent balls.

On the other hand, CSPs are optimized for size. They should cover the smallest size on the PCB so that they can be easy to integrate.

Thickness

Closely related to the size is the thickness of the package. Usually, the thickness is determined by the number of layers in the package.

The BGA package is thicker than the CSP package. The thickness is caused by the solder balls that are at the bottom of the package. On the other hand, the low profile of CSP makes them thinner than BGA.

Cost

When it comes to the price of IC packages, BGA is more expensive than CSP packages. This is mainly based on the complexity of manufacturing. BGS requires high levels of precision to manufacture. This is unlike CSP which features simple design and structure.

Conclusion

So, which one should I choose between the BGA and CSP packages? We have outlined the clear differences between these two types of IC packages. Your task is to do a comprehensive comparison and analysis of the two. From there, you can turn your full attention to your application needs.

At the end of the day, you will be able to choose the right IC packaging that is perfect for the needs of your products and applications.

If you are not sure of the IC package to choose between the ball grid array and CSP, you should consider consulting experts in the field. They will analyze your needs and guide you on how to make the right selection.

Furthermore, where you buy integrated circuits matters. The right suppliers will not hesitate to give you full guidance on the packaging type that has been used on their ICs. For example, ICRFQ has technical sales reps and customer care reps who will give you full information on the difference between BGA and CSP packages.

Kevin Chen

Founder / Writer at Rantle East Electronic Trading Co.,Limited

I am Kevin Chen, I graduated from University of Electronic Science and Technology of China in 2000. I am an electrical and electronic engineer with 23 years of experience, in charge of writting content for ICRFQ. I am willing use my experiences to create reliable and necessary electronic information to help our readers. We welcome readers to engage with us on various topics related to electronics such as IC chips, Diode, Transistor, Module, Relay, opticalcoupler, Connectors etc. Please feel free to share your thoughts and questions on these subjects with us. We look forward to hearing from you!

Start With

Start With Include With

Include With