What is Advanced Semiconductor Packaging Technology?

What is Advanced Semiconductor Packaging Technology?

Image source LinkedIn

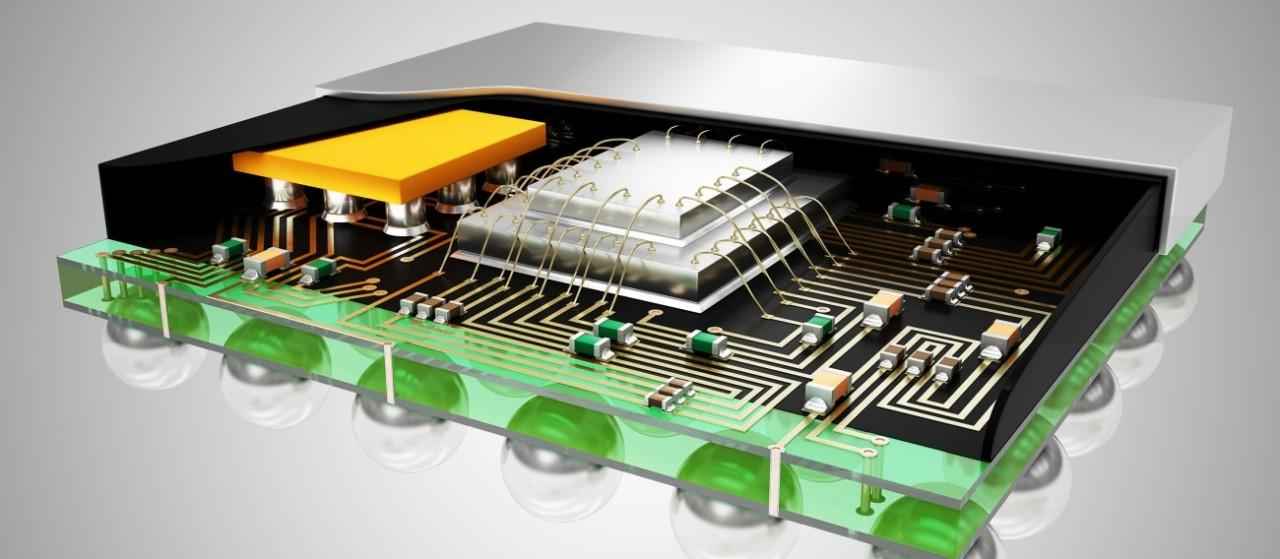

Advanced semiconductor packaging refers to an aggregation of sophisticated technologies that are geared towards encapsulating and housing integrated circuits, or semiconductor chips. These packaging methodologies aim at creating not only highly protective packages but also optimizing the performance of semiconductor chips in all the available conditions.

Advanced packaging for semiconductor chips is replacing the traditional circuit packaging methods, which in most cases entailed packaging a single die per package. In the advanced solutions, multiple electronic components, and devices together with their interconnections are merged and packaged as single electronic devices.

Advanced IC packaging uses high-level techniques and processes that are usually executed at facilities that specialize in semiconductor fabrication. They have the features of both semiconductor fabrication and traditional IC packaging techniques.

If you are planning to buy semiconductor chips, it is important to have adequate knowledge about the type of packaging that has been used.

In this article, we are going to discuss everything that you should know about advanced semiconductor packaging technology. You will learn the key elements of this technology and why most IC manufacturers are embracing it over traditional semiconductor packaging methods.

Key parameters for the advanced semiconductor packaging

Advanced semiconductor packaging technology is shaped by three major parameters. These are power, performance, surface area, and the cost of packaging. Let’s have a brief look at the beach of these parameters and their relationship in the area of advanced packaging.

· Power in the semiconductor chip packaging covers the utilization and management of power. The packaging should ensure that semiconductor chips can manage power efficiently with minimal wastage. This should be possible regardless of the type of chip that is used.

· Performance: Semiconductor chip packaging, to some extent has a direct impact on the performance of the IC. Advanced packaging is tailored towards enhancing the performance of the IC in their respective application areas.

· Surface area: What is the impact of the packaging type on the total surface area of the chip? Area, or form factor is among the issues that advanced packaging tries to solve. The advancement is mainly geared towards a small area or form factor. This should be achieved without hurting the power and performance of the IC.

· Cost: How much does it cost to implement a semiconductor packaging type? The choice of material and the fabrication process are among the key factors that determine the cost of semiconductor packaging.

When all these parameters are considered, the result is an advanced semiconductor packaging technology that is tailored to meet the needs of different modern applications.

2.5 semiconductor packaging

Also known as 2.5D interposer technology, this is one of the most advanced semiconductor technologies in the market. It sits right in the middle of 2D and 3D packaging technologies, and this is where it derives its name.

2.5D packaging technology entails the placement of multiple dies side by side on a silicon interposer. These dies are not uniform since they are sourced from different technologies. However, they are designed to be compatible with each other.

The interposer in this packaging acts as a bridge. It provides a perfect and seamless connection between individual dies for fast connection. The placement of dies side by side enhances the speed and flexibility of the semiconductor chip.

The most common 2.5D technology features a combination of a silicon interposer with a TSVS. A silicon substrate serves as an interposer and is connected to the dies using a Bump connection. TSVS are used for creating electric connections between silicon layers to form complete and functional integrated circuits.

2.5D packaging technology is ideal for chips that have large surface area yet you want to achieve high pin density.

Advantages of 2.5D technology

Some of the key benefits that are associated with 2.5D packaging include:

· Improved performance: With 2.5D packaging, IC manufacturers can integrate many different components such as processors, sensors, and memory modules into a single package. This is because it minimizes the need for using long connections and also the components are just next to each other. The result is enhanced performance.

· Compact: Size reduction is among the chief benefits of using 2.5D packaging for semiconductor modules. The fact that the dies are well-stacked on an interposer means that a very small footprint will be used. The compact size means that the packaging is ideal for small devices and appliances.

· Energy efficiency: 2.5D packaging is highly characterized by high levels of energy efficiency. The short interconnects between the electronic components mean that minimal energy is needed to facilitate signal transfer. Power efficiency is quite a desirable feature on battery-powered devices.

What is 3D packaging?

3D packaging elevates the IC packaging to the next level. It entails stacking multiple semiconductor dies on top of each other. This ends up creating a 3D structure hence the name.

3D packaging for semiconductors also enhances the performance of an integrated circuit. This is in addition to more functionality and as well as a shorter footprint of the IC. Wafers are intricately stacked on top of each other to achieve maximum integration. This not only saves space but also guarantees performance.

3D system-on-chip is one of the most common category types of 3D semiconductor chip packaging. It is also characterized by stacking wafers on top of each other.

The benefits of 3D semiconductor packaging are similar to those of 2.5D packaging. They include compactness, high performance, enhanced functionality, and also power efficiency.

Applications of advanced semiconductor packaging

Given their properties and features, most advanced semiconductor packaging solutions are used in high-performance computing devices and appliances.

These applications include advanced networking devices and as well as high-capacity data centers. They are also used in artificial intelligence applications.

Another common application is in high-level security systems. These packaging solutions guarantee speed and performance on devices that are used in the security industry.

Compactness and power efficiency make advanced IC packaging suitable candidates for mobile devices. It is easy to embed these semiconductor chips into mobile electronic devices. They are also efficient when it comes to consuming power from charged batteries.

In conclusion, advanced semiconductor packaging is the current and the future of IC packaging. In case you are buying ICs, ensure that you confirm the type of packaging that has been used. Working with reputable IC suppliers such as ICRFQ will ensure that you end up with the best packaging.

Kevin Chen

Founder / Writer at Rantle East Electronic Trading Co.,Limited

I am Kevin Chen, I graduated from University of Electronic Science and Technology of China in 2000. I am an electrical and electronic engineer with 23 years of experience, in charge of writting content for ICRFQ. I am willing use my experiences to create reliable and necessary electronic information to help our readers. We welcome readers to engage with us on various topics related to electronics such as IC chips, Diode, Transistor, Module, Relay, opticalcoupler, Connectors etc. Please feel free to share your thoughts and questions on these subjects with us. We look forward to hearing from you!

Start With

Start With Include With

Include With