Everything You Need To Know About IGBT Module

Everything You Need To Know About IGBT Module

Are you planning to buy IGBT? Whether it is for personal or industrial applications, it is important to have the right information about these products. Buying IGBT in bulk is quite an investment. With the right information, you will eventually end up with the best insulated-gate bipolar transistor. Well, this is the actual purpose of this article. We are going to discuss every vital information that you should know about IGBT. You will also learn how IGBTs work and how to use them in your application. What should I look out for when buying IGBTs? Well, you will get information about this in this article.

What is IGBT?

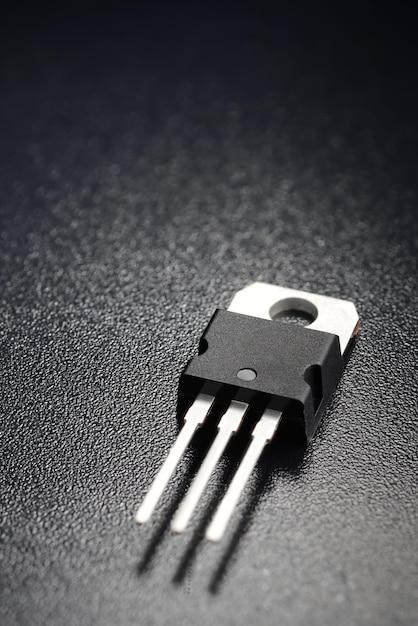

IGBT stands for insulated-gate bipolar transistor. This is a three-terminal semiconductor device that is mainly used in power applications to serve as a switch. The transistor utilizes the fast-switching speed and efficiency of transistors to perform its tasks. A typical IGBT comprises four layers of P-N-P-N and the behavior of these layers is controlled by the MOS gate structure.

In terms of the structural arrangement, we can compare IGBT to a thyristor that has a MOS gate. This gate controls and suppresses the action of the thyristor.

The structural arrangement of the transistor gives it the capacity to handle large amounts of current. Without affecting the switching speed. This implies that IGBT modules are fully capable of handling large collector-emitter currents.

The four alternating layers of P and N materials end up forming three terminals that determine the direction of the current flow. A metal-oxide-semiconductor gate (MOS gate) determines or controls the direction of the current. However, take note that these terminals are unidirectional. This means that current can only flow when forward-biased. This feature separates IGBT from MOSFETs where the current flow is bidirectional.

IGBT structure and construction

The structure of IGBT comprises four layers of semiconductor materials that are stacked together to form a single electric device. These layers are the P-layer (close to the collector terminal), N-layer, P layer (close to the emitter terminal), and N+ layer that is embedded within the layer.

The whole structure of the IGBT is built on the n-type substrate while the p-type substrates are added at the very top end. Two n+ layers are embedded inside the players and they end up forming the emitter terminal of the IGBT.

The n-channel is used for the current conduction. The n-layer ends up forming the drift layer of the IGBT. The drift layer is designed to increase the voltage rating of the IGBT. This explains why IGBT is capable of powering high-voltage applications.

How does an IGBT work?

Since IGBT has a similar structure to that of MOSFET, they tend to have almost the same working principle. The gate terminal of the IGBT is directly connected to its emitter terminal through a positive voltage source such as a battery. The emitter terminal of the IGBT is then connected to the negative terminal of the battery. The connections create a voltage drop between the emitter and the gate terminals(Vge) which serves as the controlling input voltage. It controls the output current that will pass through the collector (Ic).

When it comes to the operation, an IGBT will be at the cut-off mode when no current is flowing through the emitter to the collector terminals. When a small amount of current flows through the collector to the emitter, it will accumulate to form the Vge. This is the conduction mode of the IGBT and there is maximum flow of electric current through the transistor. The small current at the gate of the transistor is enough to keep the IGBT in an on state for a long period.

When the diode is not in the conduction mode, it is in the blocking mode. Here, it is literally in an OFF state. How is that mode created? This happens when the IGBT blocks the electric current from flowing from the collector to the emitter. Electric loads or devices that are connected to the IGBT will remain in an off state unless the connection is reversed. The two states can change pretty fast and within a short time. This explains the switching capability of the IGBT.

Types of IGBT

There are two main types of IGBTs namely Punch Through IGBT (PT-IGBT) and Non-Punch Through IGBT NPT-IGBT). The most common difference between them is that PT-IGBT has an asymmetrical configuration while NPT-IGBT has a symmetrical configuration.

Beyond the configuration, the two also differ in terms of their performance levels. PT-IGBT experiences a low conduction loss with every increase in temperature. On the other hand, NPT-IGBT has high conduction loss that is completely independent of temperature changes.

In terms of thermal stability, NPT-IGBT has a better thermal stability than the PT-IGBT. This means that it can still perform pretty well in different temperature conditions. Additionally, NPT-IGBT has a longer lifetime than the PT-IGBT.

NPT-IGBT and PT-IGBT have different application areas. PT-IGBT is mainly used in DC circuits while NPT-IGBT is mainly used in AC circuits.

Applications of IGBT modules

Common uses of IGBT include:

· DC-AC inverters

· Switch mode in power systems

· In-drive motors and as well as motor controls

· Pulse-width modulators

· Inductive load drivers

Advantages of IGBT?

Some of the reasons why IGBT is used in electronic applications include but not limited to:

· Simple structure and design hence are easy to integrate into electric circuits

· Fast switching speed

· Thermal stability is rarely affected by drastic changes in temperatures. It also operates at wide temperature ranges

· Low resistance

· High current density hence suitable for applications that need to be powered by high current

· High voltage capacity

· Compact size makes it easy to handle and use

· Highly energy-efficient. This is due to several factors among them it has a low on-state power dissipation. This means that it uses minimal power when in on-state.

Limitations of the IGBT module

Despite being an ideal alternative to most electronic components, some limitations are associated with using IGBT. The most common issue is the initial cost of the component. It is more expensive than most of its alternatives. However, with the advancement of manufacturing technologies, the prices of the IGBT modules have been coming down. You should also strive to buy from affordable sources.

FAQs about IGBT

Here are some of the frequently asked questions about insulated-gate bipolar transistors:

How do you test IGBTs?

Testing an IGBT usually comes in handy whenever you want to identify each terminal of the transistor. You can easily use a multimeter to test your IGBT. With this tool, you will be able to test the conductivity of the transistor and even tell which terminals are conducting electric current and which ones are not. While a multimeter can be ideal for the basic tests, you can carry out deeper tests on the IGBT. However, this will require an expert’s hand. They will be able to diagnose and test other electrical properties of the IGBT. Keep in mind that you should follow and observe all the necessary safety requirements when testing insulated-gate bipolar transistors. Just like other electronic devices, there are some serious risks associated with poor handling of the IGBT.

How do I control IGBT? Controlling IGBT is done through its gate terminal. By activating and deactivating this terminal, you will be able to control the flow of electric current in the IGBT. In case you want the IGBT to be on, you will apply a positive input voltage at the gate terminal. This will allow current to flow from the gate to the emitter hence keeping the IGBT active. The fact that IGBT is a voltage-controlled device means that you only need to apply a small voltage at the gate terminal and it will be able to maintain the electrical conductivity of the IGBT for an extended period. You can deactivate the IGBT by simply changing the input voltage that is connected to the gate terminal to zero.

What are IGBTs mainly used for?

Insulated-gate bipolar transistors are mainly used as switching devices. They are commonly found in inverter circuits (circuits that switch from DC to AC). In such circuits, IGBT plays an important role in driving small and large motors. Applications that depend on inverter circuits include refrigerators, air conditioners, automotive motors, motor controllers, and industrial motors. The fast-switching speeds of IGBTs guarantee the energy efficiency of the devices.

How do I know if I have IGBT or MOSFET?

There is a striking similarity between IGBTs and MOSFETs. Both have three terminals and you can easily confuse one with another. As we have discussed, the three terminals on IGBT are the Gate (G), Collector (C), and Emitter (E). On the other hand, the terminals on the MOSFET are the Gate (G), Drain (D), and the Source (S). You should make efforts to point out the unique properties of both terminals so that you don’t confuse the two.

How many terminals does IGBT have?

A typical insulated-gate bipolar transistor has three terminals. These terminals are designed to combine the desirable characteristics of a bipolar junction transistor. The three terminals are the emitter, the gate, and the collector. The base and the emitter provide paths for the electric current while the gate functions as a control terminal.

How does IGBT convert DC to AC?

IGBT utilizes its switching mechanism to facilitate the conversion of power from DC to AC. Through the switching mechanism, IGBT changes the state of the circuit between On and Off. While doing so, t creates pulse waves that have varying widths. These pulse waves are then combined to form a sine wave which in the world of electronics is known as pulse width modulation, a key property of the alternating current.

How many types of IGBT are there?

There are two main types of insulated-gate bipolar transistors. These are Punch through IGBT and non-punch through IGBT. The two types have different physical and electrical properties. Before you choose any type, it is important to have adequate information about it. The good news is we have covered the two types of IGBT in detail and you should be able to tell the difference between the two. You can then compare them and finally choose one that is suitable for your application field.

Can an IGBT be used in synchronous rectifier mode?

Technically, the IGBT can't work in a synchronous rectifier mode. This is mainly because IGBTs are not designed to conduct electric current when they are reverse-biased. Current in this device cannot flow from the emitter to the collector. When connected to a positive input voltage. This is based on the fact that IGBTs feature a bipolar-type structure.

What can cause an IGBT to fail?

Common types of failures in IGBTs include short circuits, the inability of the gate to control the terminal, and current leakage. Several factors can cause such types of failure. Extreme environmental temperature is one of the factors. Also, high voltage and current can cause short circuits. Extreme operating conditions such as overheating will also lead to some form of failure.

Conclusion

IGBT modules play an important role in modern electronics. We have just seen some of their main application areas. I hope that with this article, you have equipped yourself with adequate information about these semiconductor power modules. In case you were planning to buy one, you can proceed to do so with full confidence.

Implement all the tips that we have mentioned and you will eventually end up with the right IGBT. In case you are planning to buy IGBT in bulk, you should prioritize working with the right suppliers and distributors. A global and reputable IGBT distributor such as Rantle East Electronic should be your top priority.

Rantle East Electronic is a reputable electronic component distributor and IGBTs are among the products that you will find from us. We have been in the industry for over 20 years and are always committed to working with our customers so that they can get the best products. Contact us directly for premium-quality IGBT modules.

Kevin Chen

Founder / Writer at Rantle East Electronic Trading Co.,Limited

I am Kevin Chen, I graduated from University of Electronic Science and Technology of China in 2000. I am an electrical and electronic engineer with 23 years of experience, in charge of writting content for ICRFQ. I am willing use my experiences to create reliable and necessary electronic information to help our readers. We welcome readers to engage with us on various topics related to electronics such as IC chips, Diode, Transistor, Module, Relay, opticalcoupler, Connectors etc. Please feel free to share your thoughts and questions on these subjects with us. We look forward to hearing from you!

Start With

Start With Include With

Include With