The Comprehensive Guide to Rectifier Circuits

A rectifier circuit is an essential electronic device that converts alternating current (AC) to direct current (DC). This conversion is critical for powering most electronic devices, which require stable DC voltage. Rectifiers are foundational components in power supplies, battery chargers, and industrial systems. This article explores the types, operation, design considerations, and applications of rectifier circuits.

Types of Rectifier Circuits

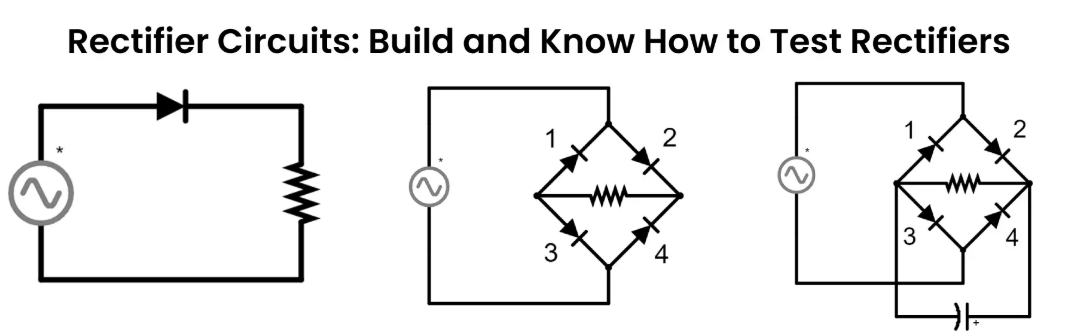

1. Half-Wave Rectifier

Operation:

Uses one diode to allow current flow only during the positive half-cycle of the AC input.

The diode blocks the negative half-cycle, resulting in a pulsating DC output.

Key Parameters:

Average Output Voltage (V_avg): (where is peak input voltage).

RMS Output Voltage (V_rms): .

Ripple Factor: .

Efficiency: ~40.6%.

Peak Inverse Voltage (PIV): .

Advantages:

Simple design, low cost.

Disadvantages:

High ripple, low efficiency, poor utilization of the AC input.

Applications:

Low-power devices (e.g., simple battery chargers, signal demodulation).

2. Full-Wave Rectifier

a) Center-Tapped Rectifier

Operation:

Uses two diodes and a center-tapped transformer.

Each diode conducts during alternate half-cycles, utilizing both halves of the AC input.

Key Parameters:

Average Output Voltage: .

RMS Output Voltage: .

Ripple Factor: ~0.48.

Efficiency: ~81.2%.

PIV: (per diode).

b) Bridge Rectifier

Operation:

Uses four diodes in a bridge configuration without a center-tapped transformer.

Two diodes conduct during each half-cycle, enabling full-wave rectification.

Key Parameters:

Average Output Voltage: (accounts for two diode drops ).

RMS Output Voltage: Same as center-tapped.

Ripple Factor: ~0.48.

Efficiency: ~81.2%.

PIV: .

Advantages:

Higher efficiency, smoother output, no need for a center-tapped transformer (bridge).

Disadvantages:

Center-tapped requires bulky transformers; bridge uses more diodes.

Applications:

Power supplies for TVs, computers, and LED drivers.

Filter Circuits

To reduce ripple, capacitors are added parallel to the load:

The capacitor charges to the peak voltage during conduction and discharges during non-conduction periods.

Ripple Voltage: , where is the ripple frequency (double the input frequency for full-wave).

Larger capacitors or higher frequencies minimize ripple.

Three-Phase Rectifiers

Used in industrial applications for high-power DC loads:

Six-Diode Bridge: Converts three-phase AC to DC with minimal ripple (~4% compared to 48% in single-phase).

Advantages: High efficiency, low ripple, continuous power delivery.

Applications: Motor drives, welding, HVDC transmission.

Design Considerations

Diode Selection:

PIV Rating: Must exceed the maximum reverse voltage (e.g., for center-tapped).

Forward Current Rating: Should handle peak load current.

Voltage Drop: Silicon diodes have ~0.7V drop each (e.g., 1.4V total in bridge rectifiers).

Transformer Specifications:

Center-tapped transformers must match voltage requirements.

Thermal Management:

Heat sinks prevent diode overheating due to power dissipation ().

Filter Capacitors:

Voltage rating must exceed peak output voltage.

Efficiency vs. Cost:

Bridge rectifiers balance efficiency and transformer simplicity.

Applications

Consumer Electronics: Power adapters, LED drivers.

Industrial: Battery charging, electroplating, welding.

Renewable Energy: Solar inverters, wind turbine converters.

Transportation: Electric vehicle chargers.

Conclusion

Rectifier circuits are pivotal in modern electronics, transforming AC to usable DC. The choice between half-wave, full-wave, or bridge rectifiers depends on efficiency, cost, and application requirements. Incorporating filters and regulators further refines the DC output, ensuring stable power delivery. Understanding diode characteristics, transformer design, and thermal management is crucial for effective rectifier implementation. As technology advances, synchronous rectifiers using MOSFETs are emerging for higher efficiency in compact devices.

Kevin Chen

Founder / Writer at Rantle East Electronic Trading Co.,Limited

I am Kevin Chen, I graduated from University of Electronic Science and Technology of China in 2000. I am an electrical and electronic engineer with 23 years of experience, in charge of writting content for ICRFQ. I am willing use my experiences to create reliable and necessary electronic information to help our readers. We welcome readers to engage with us on various topics related to electronics such as IC chips, Diode, Transistor, Module, Relay, opticalcoupler, Connectors etc. Please feel free to share your thoughts and questions on these subjects with us. We look forward to hearing from you!

Start With

Start With Include With

Include With