How To Choose Electronic Connectors: The Ultimate Guide

Electronic connectors are critical components in virtually all electrical and electronic systems, enabling reliable signal and power transmission between subsystems. Selecting the right connector requires careful consideration of technical, environmental, and economic factors. This guide provides a systematic approach to connector selection.

1. Define Application Requirements

Start by clearly documenting your system's needs:

Electrical Parameters

Current rating (1A to 500A+)

Voltage requirements (5V DC to 100kV AC)

Signal frequency (DC to GHz range)

Contact resistance (<20mΩ for power applications)

Mechanical Constraints

Available PCB space/panel cutout

Mating cycle requirements (10 cycles vs 10,000+)

IP rating (IP67 for outdoor vs IP20 for indoor)

Environmental Conditions

Temperature range (-55°C to 200°C)

Vibration/shock (MIL-STD-202H standards)

Chemical exposure (salt spray, fuels)

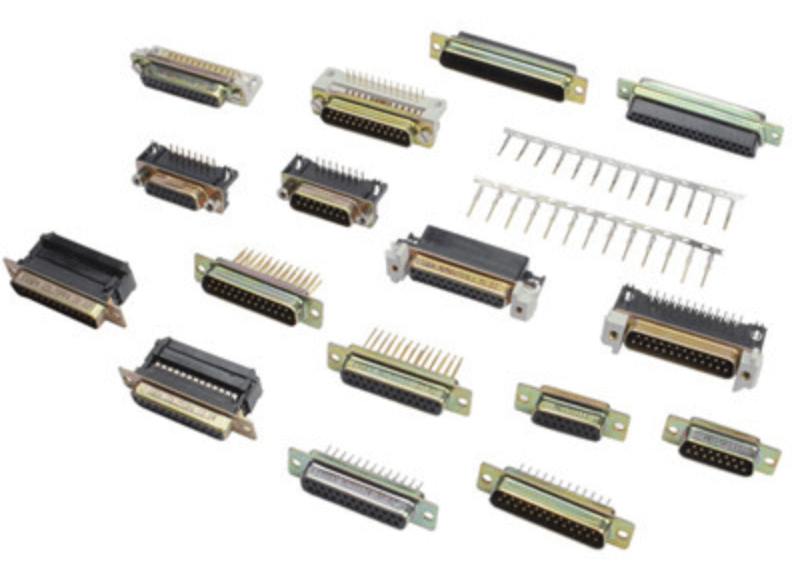

2. Connector Types & Topologies

Choose from these common configurations:

| Type | Characteristics | Typical Use |

|---|---|---|

| Board-to-Board | 0.4mm~2mm pitch | Consumer electronics |

| Wire-to-Board | IDC, crimp, solder | Industrial controls |

| Circular | MIL-DTL-5015 | Aerospace/military |

| Rectangular | D-Sub, HDMI | Data transmission |

| RF | SMA, N-Type | Wireless systems |

| Fiber Optic | LC, SC | High-speed data |

3. Contact Technology Selection

Critical for signal integrity and durability:

Contact Plating Options

Gold (0.4-1.27μm): >100,000 cycles

Silver: High current but tarnishes

Tin: Low cost, limited cycles

Termination Methods

pythonCopydef select_termination(current): if current > 10A: return "Crimp or weld" elif 1A < current <= 10A: return "Solder cup" else: return "Surface mount"

4. Environmental Compliance

Meet industry-specific certifications:

Automotive: USCAR-2, LV214

Aerospace: AS39029

Industrial: UL1977, IEC 61076

Medical: ISO 13485

5. Signal Integrity Considerations

For high-speed applications (≥1Gbps):

Use controlled impedance connectors (±5Ω tolerance)

Implement ground shielding

Maintain consistent dielectric materials (ε_r 2.8~3.6)

Minimize stub lengths (<λ/10 at max frequency)

6. Reliability Engineering

Calculate expected failure rates using:Where:

= Base failure rate (e.g., 0.1 FIT)

= Temperature factor (1.5@85°C)

= Environment factor (10 for missile launch)

= Quality factor (0.1 for military grade)

7. Cost Optimization Strategies

Balance performance and budget:

Use hybrid connectors (power + signal)

Implement modular designs

Consider total cost of ownership:

"A $0.10 connector causing 1% field failures can cost $10,000 in recalls"

8. Supplier Evaluation Checklist

Manufacturing capabilities (mold precision ±0.002mm)

Testing facilities (HALT chamber, automated continuity test)

Lead time flexibility (2 weeks vs 12 weeks)

FA capabilities (SEM/EDS analysis)

9. Prototyping & Validation

Follow this test sequence:

Mechanical mating (500 cycles minimum)

Thermal shock (-55°C ? 125°C, 15 cycles)

Vibration (20-2000Hz, 3 axes)

Current cycling (0?max current, 1000 cycles)

Salt spray (96hrs per ASTM B117)

10. Industry-Specific Trends

Automotive: High-voltage connectors for EVs (up to 1500V)

5G: 64-contact QSFP-DD @ 400Gbps

Space: Hi-Rel connectors with MGSE-29600 compliance

Common Mistakes to Avoid:

Overlooking mating orientation (keying)

Neglecting creepage/clearance distances

Mismatching CTE (connector vs PCB)

Underestimating contact wear

Decision Support Tools:

TE Connectivity Connector Selector

Molex Configurable CAD Models

ANSYS HFSS for EMI simulation

By methodically evaluating these parameters and following industry best practices, engineers can select connectors that ensure optimal system performance while maintaining cost efficiency and reliability. Always request samples for real-world testing before finalizing designs.

Kevin Chen

Founder / Writer at Rantle East Electronic Trading Co.,Limited

I am Kevin Chen, I graduated from University of Electronic Science and Technology of China in 2000. I am an electrical and electronic engineer with 23 years of experience, in charge of writting content for ICRFQ. I am willing use my experiences to create reliable and necessary electronic information to help our readers. We welcome readers to engage with us on various topics related to electronics such as IC chips, Diode, Transistor, Module, Relay, opticalcoupler, Connectors etc. Please feel free to share your thoughts and questions on these subjects with us. We look forward to hearing from you!

Start With

Start With Include With

Include With