How to Choose Electronic Resistors: The Ultimate Guide

Resistors are fundamental components in electronic circuits, used to limit current flow, adjust signal levels, and divide voltages. Selecting the right resistor ensures optimal circuit performance, reliability, and cost-effectiveness. This guide covers key considerations and practical steps for choosing resistors tailored to your application.

1. Understand Core Resistor Parameters

a. Resistance Value

Definition: Measured in ohms (Ω), it determines how much a resistor opposes current flow.

Selection Tip:

Use standard E-series values (e.g., E6, E12, E24) for general-purpose applications.

For precision needs, opt for E96/E192 series or programmable resistors.

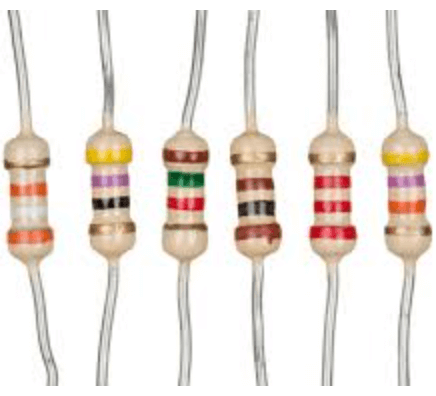

b. Tolerance

Definition: The allowable deviation from the specified resistance value, expressed as a percentage (e.g., ±1%, ±5%).

Guidelines:

±5% (Carbon Film): Suitable for non-critical applications (e.g., LED current limiting).

±1% (Metal Film): Ideal for analog circuits, filters, and voltage dividers.

±0.1% or lower (Precision Resistors): Used in medical devices, test equipment, and precision amplifiers.

c. Power Rating

Definition: Maximum power (in watts) a resistor can dissipate without damage.

Calculation:

Always derate by 50–60% for reliability (e.g., use a 0.5W resistor for a 0.25W requirement).

Common Ratings:

1/8W–1/4W: Low-power circuits (e.g., consumer electronics).

1W–5W: Power supplies, motor drivers.

≥10W: Industrial equipment (use wirewound or aluminum-clad resistors).

d. Temperature Coefficient (TCR)

Definition: Resistance change per degree Celsius (ppm/°C). Lower TCR = better stability.

Applications:

±100 ppm/°C: General use.

±25 ppm/°C: Precision analog circuits.

±5 ppm/°C: Military/aerospace systems.

e. Voltage Rating

Definition: Maximum voltage a resistor can handle without arcing or breakdown.

Rule of Thumb: Ensure operating voltage < 75% of the rated voltage.

2. Match Resistor Type to Application

| Type | Pros | Cons | Best For |

|---|---|---|---|

| Carbon Film | Low cost, widely available | High TCR (±500 ppm/°C), noise | Non-critical circuits (e.g., pull-up) |

| Metal Film | Low noise, ±1% tolerance | Moderate power handling | Analog circuits, amplifiers |

| Thick Film | Cheap, small size (SMD) | High TCR, limited precision | Consumer electronics |

| Wirewound | High power, low TCR | Inductive, bulky | Power supplies, braking resistors |

| Foil Resistors | Ultra-high precision (±0.005%) | Expensive | Medical/measurement equipment |

| Current Sense | Low TCR, low resistance (mΩ) | Specialized | Motor control, battery monitoring |

3. Environmental & Mechanical Factors

a. Operating Temperature

Ensure the resistor’s temperature range exceeds your application’s limits (e.g., -55°C to +155°C for automotive).

High-temp environments (e.g., near engines) may require ceramic or aluminum-housed resistors.

b. Humidity & Corrosion

Use conformal-coated or hermetically sealed resistors in humid or corrosive environments (e.g., marine systems).

c. Vibration/Shock

SMD resistors withstand vibration better than through-hole. For extreme conditions, use epoxy-coated wirewound resistors.

4. Specialized Applications

a. High-Frequency Circuits

Avoid wirewound resistors (inductive). Use thin-film or carbon composition for RF applications.

b. Precision Circuits

Select low-TCR (<±25 ppm/°C), low-noise resistors (e.g., Vishay Z-Foil, Bulk Metal?).

c. High-Voltage Systems

Use high-voltage resistors (e.g., Ohmite MOX) with ratings > 1 kV and adequate creepage distance.

d. Current Sensing

Choose current sense resistors (e.g., Bourns CSS2) with low resistance (1 mΩ–1 Ω) and 1% tolerance.

5. Package & Mounting

Through-Hole: Easy prototyping; suits high-power applications.

Surface-Mount (SMD): Compact, automated assembly. Common sizes:

0402/0603: High-density PCBs.

1206/2512: Higher power handling (up to 1W).

6. Cost Optimization

Avoid over-specifying. Example: Use ±5% resistors for LED circuits instead of ±1%.

Buy in bulk for standard values; consider programmable resistors for prototyping.

7. Step-by-Step Selection Process

Define Requirements:

Resistance, tolerance, power, voltage, temperature range.

Choose Type:

Metal film for precision, thick film for cost, wirewound for power.

Verify Availability:

Check distributors (Digi-Key, Mouser) for stock and lead times.

Test Prototype:

Validate thermal performance and drift under operating conditions.

8. Common Mistakes to Avoid

Ignoring Derating: Running resistors at >70% power rating reduces lifespan.

Overlooking TCR: Causing drift in temperature-sensitive circuits.

Mismatched Package: Using 0402 SMD resistors in high-vibration environments.

By systematically evaluating these factors, you can select resistors that ensure reliability, efficiency, and cost-effectiveness for your project. Always consult datasheets and test prototypes under real-world conditions.

Kevin Chen

Founder / Writer at Rantle East Electronic Trading Co.,Limited

I am Kevin Chen, I graduated from University of Electronic Science and Technology of China in 2000. I am an electrical and electronic engineer with 23 years of experience, in charge of writting content for ICRFQ. I am willing use my experiences to create reliable and necessary electronic information to help our readers. We welcome readers to engage with us on various topics related to electronics such as IC chips, Diode, Transistor, Module, Relay, opticalcoupler, Connectors etc. Please feel free to share your thoughts and questions on these subjects with us. We look forward to hearing from you!

Start With

Start With Include With

Include With