What is an Accelerometer Sensor? A Comprehensive Guide

An accelerometer sensor is a pivotal component in modern technology, enabling the detection and measurement of acceleration forces. These forces can be static, like gravity, or dynamic, resulting from movement. This article delves into the workings, types, applications, and future trends of accelerometers, providing a detailed understanding of their role in various industries.

1. Definition and Basic Principle

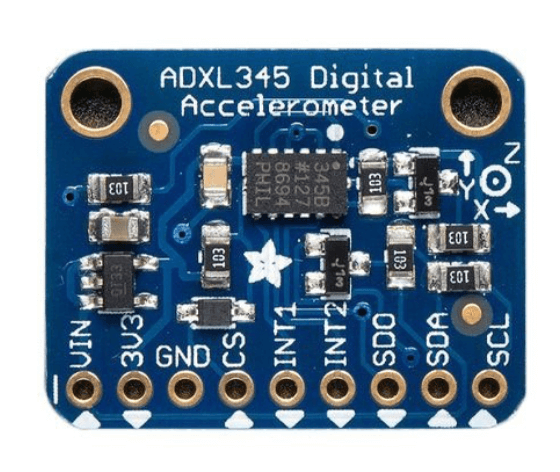

An accelerometer measures proper acceleration, which is the rate of change of velocity relative to freefall. Rooted in Newton's second law (), it detects force () exerted on a known mass () to calculate acceleration (). This allows it to sense tilt, vibration, and motion in multiple axes.

2. How It Works

MEMS Technology: Most consumer devices use Microelectromechanical Systems (MEMS) accelerometers. These consist of a suspended mass (proof mass) between capacitive plates. Acceleration displaces the mass, altering capacitance, which is converted to voltage for measurement.

Piezoelectric Effect: Some accelerometers use piezoelectric materials that generate a charge when mechanically stressed, translating force into an electrical signal.

Thermal Sensing: Less common, these measure displacement of a heated gas bubble using temperature sensors, ideal for harsh environments.

3. Types of Accelerometers

Capacitive (MEMS): Dominant in consumer electronics due to small size, low cost, and robustness.

Piezoelectric: Used in high-frequency industrial applications (e.g., vibration monitoring).

Piezoresistive: Measures resistance change under stress; suited for high-impact scenarios like automotive crash testing.

Thermal: Utilizes gas convection, resistant to shock and vibration.

4. Key Specifications

Range: Measured in (9.81 m/s2), from ±2g (smartphones) to ±500g (industrial).

Sensitivity: Resolution of detected acceleration (e.g., mV/g).

Bandwidth: Frequency range (Hz) it can capture.

Axes: 1-, 2-, or 3-axis models; 3-axis is standard for spatial tracking.

Output: Analog (voltage) or digital (I2C, SPI).

Power Consumption: Critical for battery-operated devices.

5. Applications

Consumer Electronics: Screen rotation (smartphones), gesture control (gaming controllers).

Automotive: Airbag deployment, electronic stability control.

Healthcare: Fitness trackers (step counting), pacemaker activity adjustment.

Industrial: Predictive maintenance via vibration analysis, structural health monitoring.

Aerospace: Drone stabilization, aircraft navigation.

Robotics: Balance and motion control.

6. Challenges

Noise and Accuracy: Signal interference requires advanced filtering algorithms.

Cross-Axis Sensitivity: Unwanted detection of off-axis forces.

Temperature Drift: Performance variations with temperature, necessitating compensation.

Calibration: Regular calibration ensures precision, especially in critical applications.

7. Future Trends

Miniaturization: Smaller sensors for wearables and IoT devices.

Energy Efficiency: Low-power designs for extended battery life.

Sensor Fusion: Integration with gyroscopes and magnetometers in Inertial Measurement Units (IMUs) for enhanced motion tracking.

AI Integration: Machine learning for predictive analytics in industrial maintenance.

Advanced Materials: Graphene and nanomaterials to boost sensitivity and durability.

8. Choosing an Accelerometer

Consider application-specific needs:

Range: High-g for automotive, low-g for user interfaces.

Environment: Harsh conditions may require thermal or piezoresistive types.

Output Interface: Digital for microcontrollers, analog for legacy systems.

Conclusion

Accelerometers are indispensable in bridging the physical and digital worlds, enabling innovations across industries. As technology evolves, their integration with AI and IoT promises smarter, more responsive systems, solidifying their role in the future of automation and connectivity. Understanding their principles and applications empowers engineers and consumers to leverage their capabilities effectively.

Kevin Chen

Founder / Writer at Rantle East Electronic Trading Co.,Limited

I am Kevin Chen, I graduated from University of Electronic Science and Technology of China in 2000. I am an electrical and electronic engineer with 23 years of experience, in charge of writting content for ICRFQ. I am willing use my experiences to create reliable and necessary electronic information to help our readers. We welcome readers to engage with us on various topics related to electronics such as IC chips, Diode, Transistor, Module, Relay, opticalcoupler, Connectors etc. Please feel free to share your thoughts and questions on these subjects with us. We look forward to hearing from you!

Start With

Start With Include With

Include With