What is SMT (Surface Mount Technology)?

Surface Mount Technology (SMT) is a method for constructing electronic circuits where components (Surface Mount Devices, SMDs) are mounted directly onto the surface of a Printed Circuit Board (PCB). Unlike through-hole technology (THT), which uses leads inserted into drilled holes, SMT employs smaller components soldered onto pads, enabling higher component density and miniaturization.

2. Historical Development

1960s: IBM pioneered early SMT for aerospace applications.

1980s: SMT gained traction in consumer electronics, driven by demand for compact devices.

1990s-Present: Dominates PCB assembly, enabling advancements in smartphones, IoT, and wearable tech.

3. SMT Components (SMDs)

Passive Components: Resistors (e.g., 0402: 1.0mm x 0.5mm), capacitors, inductors.

Active Components: Integrated Circuits (ICs) in packages like SOP (Small Outline Package), QFP (Quad Flat Package), and BGA (Ball Grid Array).

Advantages of SMDs: Smaller size, reduced parasitic inductance/resistance, suitability for high-frequency applications.

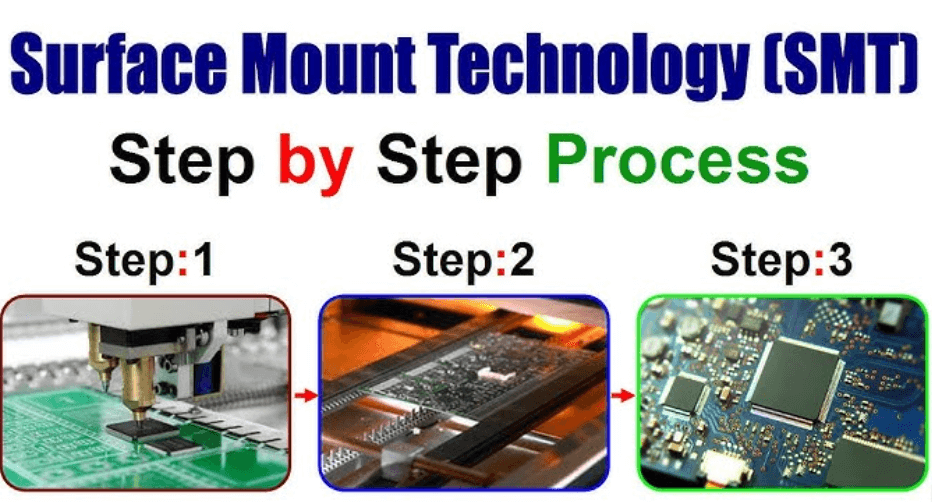

4. SMT Assembly Process

Solder Paste Application: Stencil printing deposits solder paste (flux + solder particles) onto PCB pads.

Component Placement: High-speed pick-and-place machines position SMDs with precision.

Reflow Soldering:

Preheat: Gradual temperature rise to avoid thermal shock.

Soak: Activates flux, removes solvents.

Reflow: Solder melts (220–250°C for lead-free), forming joints.

Cooling: Solidifies solder connections.

Inspection & Testing:

AOI (Automated Optical Inspection): Detects misalignment or solder defects.

X-ray: Inspects BGA joints and hidden connections.

Functional Testing: Ensures circuit performance.

5. Advantages of SMT

Miniaturization: Enables compact, lightweight devices (e.g., smartphones).

High-Density Layouts: Supports double-sided PCBs and complex designs.

Performance: Shorter leads reduce inductance, enhancing high-frequency operation.

Cost-Efficiency: Automated assembly reduces labor and boosts production speed.

Reliability: Stronger solder joints under mechanical stress.

6. Challenges and Limitations

Rework Difficulty: Tiny components require specialized tools for repair.

Thermal Stress: High soldering temperatures may damage sensitive parts.

Component Availability: High-power or large components (e.g., transformers) often remain through-hole.

Initial Costs: High setup expenses for stencils and machinery.

7. Applications

Consumer Electronics: Smartphones, tablets, laptops.

Automotive: Engine control units, infotainment systems.

Medical Devices: Wearable monitors, imaging equipment.

Aerospace/Defense: Avionics, satellite systems.

8. Future Trends

Miniaturization: Adoption of 01005 (0.4mm x 0.2mm) components.

Advanced Packaging: 3D IC stacking and system-in-package (SiP) designs.

Flexible Electronics: Integration with flexible PCBs for wearables.

Sustainability: Lead-free solders and eco-friendly manufacturing processes.

9. SMT vs. Through-Hole Technology (THT)

| Feature | SMT | THT |

|---|---|---|

| Component Size | Smaller, lighter | Larger, bulkier |

| PCB Utilization | High-density, double-sided | Lower density, single-sided |

| Assembly Speed | Fast, automated | Slower, manual insertion |

| Cost | Lower for mass production | Higher for complex boards |

| High-Frequency | Superior performance | Limited by lead inductance |

Conclusion

SMT revolutionized electronics manufacturing by enabling smaller, faster, and more reliable devices. Despite challenges in rework and thermal management, its benefits in automation, performance, and scalability make it indispensable in modern electronics. As technology advances, SMT will continue to drive innovation in IoT, AI, and beyond, underpinning the next generation of electronic devices.

Kevin Chen

Founder / Writer at Rantle East Electronic Trading Co.,Limited

I am Kevin Chen, I graduated from University of Electronic Science and Technology of China in 2000. I am an electrical and electronic engineer with 23 years of experience, in charge of writting content for ICRFQ. I am willing use my experiences to create reliable and necessary electronic information to help our readers. We welcome readers to engage with us on various topics related to electronics such as IC chips, Diode, Transistor, Module, Relay, opticalcoupler, Connectors etc. Please feel free to share your thoughts and questions on these subjects with us. We look forward to hearing from you!

Start With

Start With Include With

Include With