How To Choose Electronic Capacitor? The Complete Guide

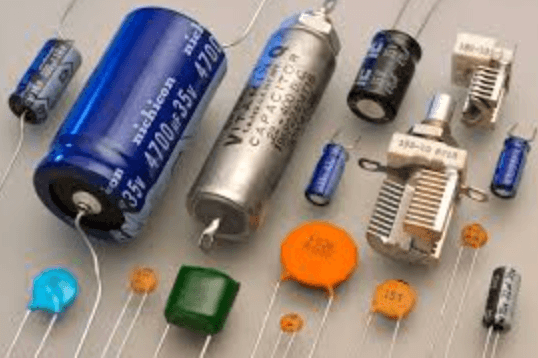

Capacitors are fundamental components in electronic circuits, serving roles from energy storage to signal filtering. Selecting the right capacitor requires understanding both your circuit’s requirements and the capacitor’s characteristics. This guide covers key parameters, capacitor types, application-specific considerations, and common pitfalls.

1. Key Parameters to Consider

A. Capacitance Value

Definition: The amount of charge a capacitor can store, measured in farads (F).

Selection: Match the value specified in your circuit design. Use standard values (e.g., 10μF, 100nF) unless precision is critical.

B. Voltage Rating

Definition: The maximum voltage a capacitor can withstand without breakdown.

Rule of Thumb: Choose a rating ≥1.5× the circuit’s operating voltage. For example, use a 25V capacitor for a 12V circuit.

C. Tolerance

Definition: The allowable deviation from the stated capacitance.

Common Tolerances:

Electrolytic: ±20% (general-purpose).

Ceramic (Class 1): ±5% (high stability).

Film: ±1–10% (precision applications).

D. Temperature Coefficient

Definition: How capacitance changes with temperature.

Critical For: Circuits operating in extreme environments (e.g., automotive, industrial).

Examples:

X7R Ceramic: ±15% over -55°C to +125°C.

C0G/NP0 Ceramic: ±0.3% (ultra-stable).

E. Equivalent Series Resistance (ESR)

Definition: Internal resistance causing energy loss.

Low ESR: Critical for high-frequency/power applications (e.g., switching power supplies).

Typical ESR Ranges:

Ceramic: 0.01–0.1Ω.

Electrolytic: 0.1–5Ω.

F. Frequency Response

Self-Resonant Frequency (SRF): The frequency at which a capacitor behaves inductively.

Rule: Select capacitors with SRF above your operating frequency (e.g., RF circuits need SRF > 1GHz).

2. Capacitor Types and Their Applications

| Type | Pros | Cons | Typical Applications |

|---|---|---|---|

| Ceramic | Low cost, small size, low ESR | Capacitance drops with voltage | Decoupling, filters, RF circuits |

| Electrolytic | High capacitance, affordable | Polarized, limited lifespan | Power supply smoothing |

| Tantalum | Stable, compact | Expensive, polarity-sensitive | Medical devices, aerospace |

| Film | High stability, low distortion | Large size | Audio circuits, timing circuits |

| Supercapacitor | Ultra-high capacitance | Low voltage rating, high leakage | Energy storage (e.g., backup power) |

3. Application-Specific Selection

A. Power Supply Circuits

Bulk Capacitance: Use aluminum electrolytic (e.g., 100–1000μF) for smoothing.

Decoupling: Pair ceramic capacitors (10nF–100nF) near ICs to suppress noise.

B. Timing/Oscillator Circuits

Stability: Use film (polypropylene) or C0G ceramic capacitors for precise time constants.

C. High-Frequency/RF Circuits

Low ESR/SRF: Opt for NP0/C0G ceramics or mica capacitors.

D. High-Temperature Environments

Reliability: Choose X7R/X8R ceramics or tantalum with ≥125°C rating.

4. Common Mistakes to Avoid

Ignoring Polarity: Reverse-biasing electrolytic/tantalum capacitors causes failure.

Overlooking Ripple Current: In power circuits, exceed the capacitor’s ripple current rating at your peril.

Mixing Dielectrics: Combining high-ESR and low-ESR capacitors in parallel can destabilize circuits.

Size vs. Performance: Miniaturized capacitors (e.g., 0201 SMD) may sacrifice voltage rating or ESR.

5. Advanced Considerations

Solid-State Capacitors: Increasing adoption in automotive/5G for longer lifespan.

MLCC Innovations: Multi-layer ceramic capacitors with higher capacitance (e.g., 100μF in 1210 size).

Sustainability: Lead-free and RoHS-compliant options are now standard.

Conclusion

Choosing the right capacitor involves balancing electrical requirements, environmental conditions, and cost. Always cross-reference datasheets and test prototypes under real-world conditions. For further guidance, consult DeepSeek’s technical resources or reach out to component manufacturers directly.

Kevin Chen

Founder / Writer at Rantle East Electronic Trading Co.,Limited

I am Kevin Chen, I graduated from University of Electronic Science and Technology of China in 2000. I am an electrical and electronic engineer with 23 years of experience, in charge of writting content for ICRFQ. I am willing use my experiences to create reliable and necessary electronic information to help our readers. We welcome readers to engage with us on various topics related to electronics such as IC chips, Diode, Transistor, Module, Relay, opticalcoupler, Connectors etc. Please feel free to share your thoughts and questions on these subjects with us. We look forward to hearing from you!

Start With

Start With Include With

Include With